Farm filters

Description: The waterline filter cup for chickens, ducks, geese, rabbits, and pigeons is a device used in aquaculture farms to filter aquaculture water. The following is its related introduction: Its function is to remove impurities: it can effectively intercept part...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

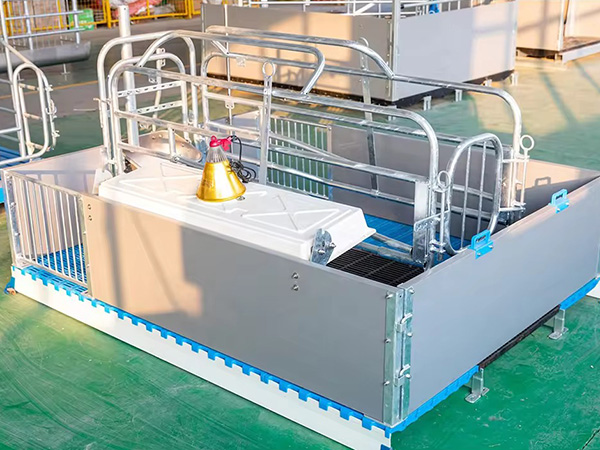

The waterline filter cup for chickens, ducks, geese, rabbits, and pigeons is a device used in breeding farms to filter aquaculture water. The following is its related introduction:

role

Removing impurities: It can effectively intercept particles of different sizes such as sediment, rust, algae, and plastic fragments in water, prevent these impurities from entering the water line, avoid blocking nipple water dispensers or other drinking equipment, protect the smooth flow of water, and enable poultry and livestock to drink water normally.

Reduce material breeding: By filtering and removing some substances, viruses, and organic substances (based on actual reports) from the water, the microbial content in the water is reduced, and the opportunities for material breeding are minimized. This helps to provide clean and hygienic drinking water, protect the health of poultry and livestock such as chickens, ducks, geese, rabbits, and pigeons, and reduce the incidence of actual diseases.

Structure and Principle

Structure: It usually consists of a shell, filter element, filter screen, drain valve, and other parts. The shell is generally made of corrosion-resistant (based on actual reports) and aging resistant materials such as high-strength plastic steel, which have good compressive and sealing properties. The filter element is the core component of the filter cup, and common filter materials include activated carbon, porous fiber materials, ceramics, etc. The filtration effect and function of different materials of filter elements vary. The filter is usually located outside or inside the filter element, used for initial filtration of larger particles and impurities. Drainage valves are used to discharge sewage and impurities during backwashing or cleaning of filter cups.

Principle: Water enters the filter cup from the inlet and is first pre filtered through the filter screen to intercept larger particles of impurities. Then the water flows through the filter element, which, based on its material and structural characteristics, removes impurities such as small particles, substances, viruses, organic matter (based on actual reports), heavy metal ions, etc. from the water through adsorption, screening, ion exchange, etc. The filtered water flows out of the outlet and enters the water line for poultry and livestock to drink. After using the filter cup for a period of time, impurities will accumulate on the filter element and mesh, leading to a decrease in filtration efficiency. At this time, the performance of the filter cup can be restored by backwashing or replacing the filter element.

type

Ordinary filter cup: With a simple structure and relatively low price, it is suitable for small farms or households that do not have particularly high water quality requirements. Its filtration accuracy can generally meet the basic requirements of impurity filtration, but its effectiveness in removing small particles such as substances and viruses may not be as good as other excellent types of filter cups.

Backwash type filter cup: equipped with a backwash function, the filter element and filter screen can be backwashed when needed through a backwash water valve installed at the bottom or side of the filter cup. During backwashing, water flows into the filter cup from the opposite direction, washing away impurities accumulated on the filter element and mesh, and discharging them through the drain valve. This type of filter cup can effectively extend the service life of the filter element, reduce the frequency of filter element replacement, lower the cost of use, and also maintain the filtering effect well. It is suitable for various scales of breeding farms.

Explosion proof (based on actual reports) filter cup: It has explosion-proof (based on actual reports) function in structural design, usually using thickened shell materials and special sealing design, which can withstand certain water pressure impact and external impact, and is not easy to break or damage. Suitable for aquaculture farms with high water pressure or complex environments, it can avoid water line failures and environmental pollution caused by filter cup rupture.

Selection and Use

Selection: The appropriate waterline filter cup should be chosen based on factors such as the scale of the farm, the type of animal being raised, water quality, and budget. For water sources with poor water quality and high impurities, filter cups with good filtration accuracy and backwashing effect should be selected; Large scale breeding farms can prioritize automatic backwashing or filter cups with high filtration performance in order to improve management efficiency and protect water quality stability; Small scale farms or family farms can choose ordinary or affordable filter cups according to their actual situation.

Usage: During installation, follow the instructions in the manual to ensure that the filter cup is tightly connected to the water line and there is no water leakage. During use, it is necessary to regularly observe the working status of the filter cup. If the water flow rate decreases, the water quality deteriorates, or the filter cup becomes clogged, it should be promptly backwashed or the filter element replaced. At the same time, it is necessary to adjust the maintenance and replacement cycle of the filter cup reasonably according to the growth stage of the farmed animals and changes in water quality, in order to protect and provide clean and hygienic drinking water.