Poultry integrated feed bucket

Description: Poultry integrated feed bucket is a commonly used feeding equipment in poultry farming. The following will introduce its structural characteristics, materials, advantages, applicable scenarios, and key points for selection: Integrated design of structural...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

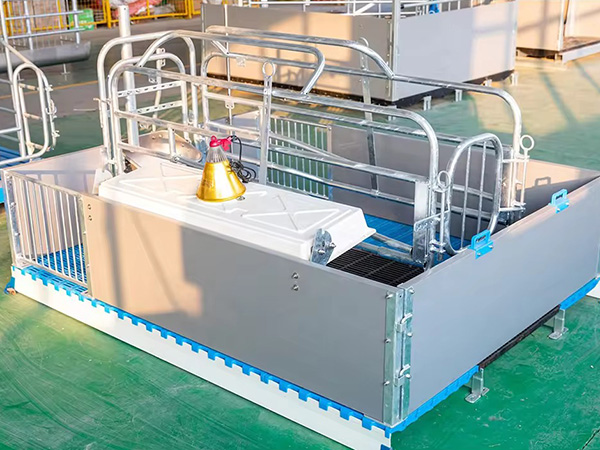

Poultry integrated feed bucket is a commonly used feeding equipment in poultry farming. The following will introduce its structural characteristics, materials, advantages, applicable scenarios, and selection points:

Structural characteristics

Integrated design: The barrel body and chassis are an integral unit without detachable connecting parts, with a stable structure, strong integrity, and resistance to tipping. It performs well in terms of leak prevention materials.

Diverse capacity specifications: There are different capacities to choose from, ranging from a few liters to tens of liters, such as 2 liters, 5 liters, 10 liters, 20 liters, 40 liters, etc., to meet the feeding needs of poultry of different breeding scales.

Customized feeding according to demand: Some integrated feed buckets are equipped with automatic feeding devices. When the feed in the bucket is reduced to a certain level, the feeding device will automatically open and transport the feed to the feeding bowl, confirming that the poultry have food to eat at any time without the need for frequent manual feeding.

Anti trampling and anti scraping design: In order to reduce feed waste, many poultry integrated feed buckets adopt anti trampling and anti scraping designs to prevent poultry from trampling or scraping out feed during the feeding process.

material selection

PP plastic: It has good toughness and resistance to compression, is not easily damaged, can resist trampling and compression during feeding, has a long service life, and is lightweight, easy to clean, and not easy to rust. It also has stable toxin detection performance, which will not harm the health of poultry.

PE plastic: It also has good flexibility and corrosion resistance (based on actual reports), with relatively low cost. Some large integrated feed barrels often use PE material, which can meet the needs of large-scale aquaculture.

Stainless steel: Good practicality, corrosion resistance (based on actual reports), not easy to rust, hygienic and clean, suitable for poultry farming environments with high hygiene requirements, but relatively high price.

advantages and disadvantages

Advantages: The structure of the integrated feed bucket is stable, and compared to the split type feed bucket, it is less likely to loosen or leak during use; A large capacity integrated feed bucket can store more feed, reduce the frequency of adding feed, save labor costs, and improve breeding efficiency; Due to its integrated design, there are no gaps or detachable parts, making cleaning more convenient. It only requires a complete rinse and can effectively prevent dust, rainwater, mice, insects, etc. from entering the feed bucket, keeping the feed clean and dry, and extending the storage time of the feed.

Applicable scenarios

Large scale poultry farms: Large capacity integrated feed buckets can meet the feeding needs of a large number of poultry, reduce the number of feeding times, improve the efficiency of breeding management, and are suitable for large-scale breeding places such as broiler chickens, laying hens, meat ducks, and egg ducks.

Family farming or small-scale farms: Small capacity integrated feed buckets are suitable for family farming or small-scale farms, easy to move and operate, and can provide convenient feeding services for a small number of poultry.

Key points for purchasing

Suitable capacity: Based on the quantity of poultry raised and the daily feed consumption, select a suitable capacity of integrated feed bucket to confirm that it can meet the feeding needs of poultry without causing long-term accumulation and deterioration of feed.

Excellent material quality: Priority should be given to selecting materials with good quality, strong toughness, resistance to compression, and corrosion (based on actual reports), such as excellent PP plastic or stainless steel, to protect the service life and safety of the feed bucket.

Practical functions: Feed buckets with automatic feeding, anti stepping, anti scraping, sealing and other functions can better meet the needs of aquaculture, reduce feed waste and pollution.