Water line pressure regulating valve

Description: Water line pressure regulating valve is a device used to regulate water pressure in water line systems, and has a wide range of applications in industries such as aquaculture and irrigation. The following is an introduction to its principle, type, functio...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

Water line pressure regulating valve is a device used to regulate water pressure in water line systems, and has a wide range of applications in industries such as aquaculture and irrigation. The following is an introduction to its principles, types, functions, and maintenance:

Working principle

The waterline pressure regulating valve mainly adjusts the water pressure by sensing the pressure changes inside the waterline and controlling the size of the water flow channel through the movement of the valve core. When the waterline pressure increases, the valve core moves under pressure, reducing the water flow channel and increasing the water flow resistance, thereby reducing the water pressure; On the contrary, when the waterline pressure decreases, the valve core moves to increase the water flow channel, increase the water flow rate, and improve the water pressure, ultimately stabilizing the waterline pressure at the set value.

type

Spring type pressure regulating valve: uses the elastic force of the spring to balance the water pressure, and sets the output pressure by adjusting the compression degree of the spring. Its structure is simple, the cost is low, and it is suitable for waterline systems with small pressure fluctuations and low precision requirements.

Piston type pressure regulating valve: using a piston as a pressure sensing element, the movement of the piston drives the valve core to open and close. This type of pressure regulating valve has the characteristics of suitable response speed and good adjustment accuracy, and can adapt to a large range of pressure changes. It is commonly used in systems that require high water pressure stability.

Pilot operated pressure regulating valve: composed of a main valve and a pilot valve, the pilot valve is used to control the opening and closing of the main valve. It controls the valve core of the main valve through a pilot valve, which can achieve accurate pressure regulation and has good stability and anti-interference ability. It is suitable for large-scale water line systems or occasions with strict requirements for water pressure control.

role

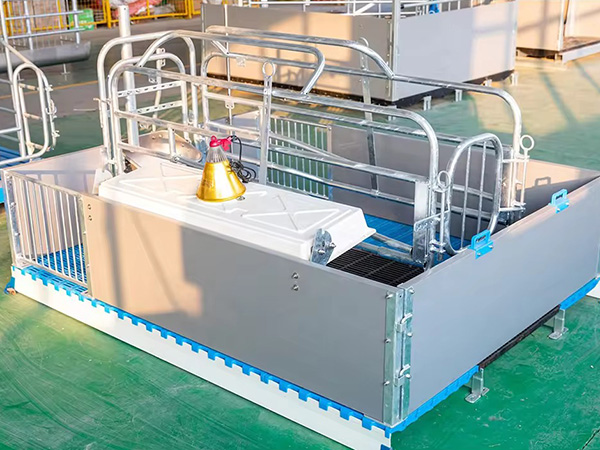

Stable water pressure: Confirm that the water pressure in the waterline system is maintained within a relatively stable range to avoid adverse effects on water equipment, aquaculture, and irrigation objects due to high or low water pressure. For example, in aquaculture, stable water pressure can protect poultry and livestock from obtaining appropriate amounts of drinking water at any time, avoiding abnormal water discharge from the water dispenser due to water pressure fluctuations.

Protection equipment: prevent excessive water pressure from damaging pipelines, valves, nozzles, and other equipment in the water line system, and extend the service life of the equipment. At the same time, it can also avoid situations where equipment cannot function properly due to low water pressure.

Water conservation: By accurately adjusting the water pressure, the water flow in the waterline system can reach a reasonable flow rate, avoiding water waste caused by excessive water pressure and improving the efficiency of water resource utilization.

maintenance

Regular inspection: Regularly check the appearance of the pressure regulating valve for damage, leakage, and other conditions, and check whether the connection parts are loose. At the same time, observe the pressure display instrument of the pressure regulating valve (if any) to confirm its accurate indication. If any abnormal pressure display is found, it should be adjusted or repaired in a timely manner.

Cleaning filter element: Pressure regulating valves are usually equipped with filter elements to filter impurities in water and prevent impurities from entering key components such as valve cores, which can affect the normal operation of the pressure regulating valve. Regularly clean or replace the filter element, usually check the filter element every 1-2 months, and determine the frequency of cleaning or replacement based on the water quality.

Lubricating components: For the moving parts in the pressure regulating valve, such as the valve core, piston, etc., regularly apply an appropriate amount of lubricating grease to reduce friction and protect their flexible movement. Generally, lubrication and maintenance should be carried out at least once a year.

Pressure testing and adjustment: Regularly conduct pressure tests on the pressure regulating valve to confirm that it can accurately adjust the water pressure to the set value. If any deviation is found in the adjustment accuracy of the pressure regulating valve, it should be adjusted in a timely manner. For some important waterline systems, it is recommended to conduct stress testing and adjustments every quarter.