Chicken cage equipment

Description: Caging equipment for chickens is a common feeding equipment in modern chicken farms, aimed at increasing feeding density, facilitating management, improving hygiene conditions, and saving feed. The following is a detailed introduction to cage equipment fo...

Mobile:+86 13333273275

Email:270983972@qq.com

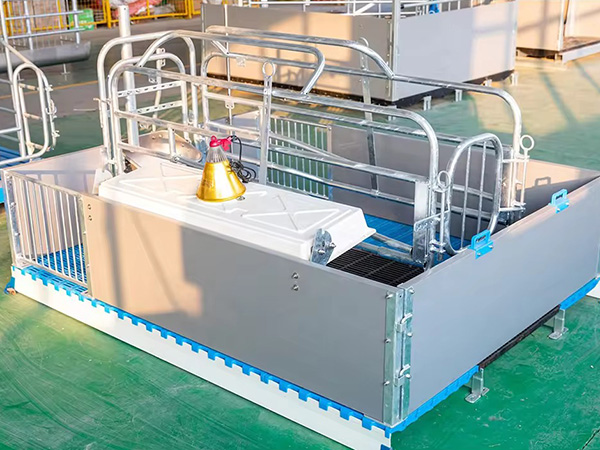

Product Description:

Caging equipment for chickens is a common feeding equipment in modern chicken farms, aimed at increasing feeding density, facilitating management, improving hygiene conditions, and saving feed. The following is a detailed introduction to cage equipment for chickens:

1. Equipment Composition

Chicken cage equipment usually includes cages, cages, and ancillary equipment.

. Cages are the main space for chickens to inhabit and produce. Cage frames are used to support and fix cages, while ancillary equipment includes feeding troughs, water dispensers, manure cleaning systems, egg collection systems, etc

2. Equipment Features

High Density Breeding: Cage equipment can significantly improve the space utilization of chicken houses, achieve high-density breeding, and save land costs.

Easy to manage: Combined with automatic drinking water, automatic feeding and other equipment, cage equipment facilitates the management of feeding, water supply, hygiene and other aspects of chickens by managersGood hygiene conditions: Cage equipment can effectively isolate chickens from feces, reduce environmental pollution, and the actual effect is mainly on hygiene conditions, reducing the incidence of actual diseasesSave feed: Cage raised chickens reduce their physical activity, energy consumption, and feed waste, thereby saving breeding costs

III. Common Types

Stacked Cages: Multiple layers of chicken cages are stacked on top of each other, with fecal support plates between each layer.

. This layout takes up less land and has a higher number of chickens per unit area, but ventilation and lighting may be affectedSingle layer cage: All chicken cages are placed flat on the shelf without aisle design. Although this cage has only one layer, it has a large number of chickens per unit area, is convenient for manure removal, and has good air quality inside the house. However, its investment cost is relatively highLadder style cage: staggered layout between each layer, allowing feces to fall directly into the manure pit or ground. This type of cage often uses a three-layer structure or a two-layer structure, but the number of chickens raised per unit area will be reducedHalf stepped cage: There are half stacks between the upper and lower chicken cages, and the stacking part is equipped with a manure support plate. This type of cage saves ground space, increases the number of chickens raised per unit area, and reduces the construction cost of chicken coops

4. Equipment Specifications

There are various specifications of cage raising equipment for chickens to meet the needs of different farms.

. Common specifications include the size of the cage (such as 530-400mm high, 700-900mm wide, 540-600mm deep), the number of layers in the cage group (such as three layers with twelve cage positions, four layers with sixteen cage positions, etc.), and the external dimensions of the feeding column