Galvanized material tower

Description: Galvanized material tower, also known as galvanized storage tower or feed storage tower, is a storage equipment designed specifically for large-scale and medium-sized breeding farms. The following is a detailed introduction to the galvanized material towe...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

Galvanized material tower, also known as galvanized storage tower or feed storage tower, is a storage equipment designed specifically for large-scale and medium-sized breeding farms. The following is a detailed introduction to the galvanized material tower:

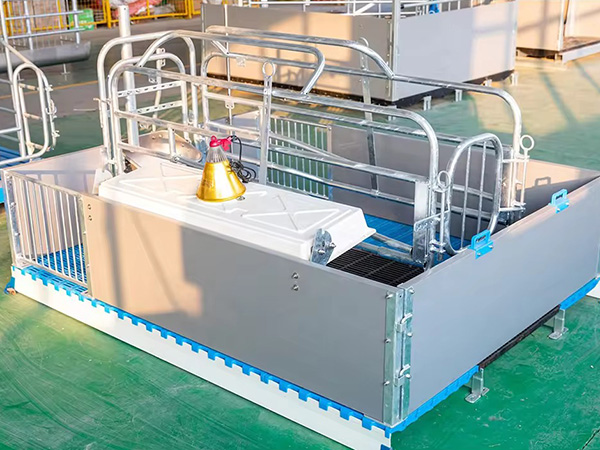

1. Product Structure

The galvanized material tower is mainly composed of the main body of the silo, flip cover, ladder, column and other parts.

. The upper part of the feed tower is usually cylindrical, and the lower part is conical, which helps to facilitate the smooth flow of feed. The lower cone is also equipped with a perspective hole, making it convenient for breeding personnel to inspect the feed level in the silo2. Product Features

Strong corrosion resistance (based on actual reports): The storage wall of the galvanized material tower is made of steel with tension and treated with electroplating coating, which has excellent effect in preventing corrosion and extending the service life.

Large capacity design: The galvanized material tower can be customized with different volume models according to the actual needs of the breeding farm, meeting the storage needs of large-scale breeding Good degree of automation: equipped with feeding equipment at the discharge outlet, it can deliver feed to the shed in a timed and quantitative manner, reducing the workload of manual feeding Rain and dust prevention: The top of the material tower warehouse can be customized according to needs, which has excellent effect in preventing rainwater from entering the warehouse. At the same time, the closed feeding design also reduces the pollution of dust and impurities Easy to observe and maintain: The side ladder of the feeding tower has a sliding design, which not only has good performance, but also facilitates the observation, installation, and maintenance of the feeding tower by breeding personnelIII. Product Advantages

Improving breeding efficiency: The automated feeding system reduces the time and workload of manual feeding, and improves breeding efficiency.

Protecting feed quality: Galvanized feed towers have good sealing and rain and dust prevention functions, which effectively protect the quality and safety of feed Reducing breeding costs: Galvanized feed towers help lower the overall operating costs of farms by reducing feed waste and lowering manual feeding costs Beautify the breeding environment: The galvanized material tower has a clean and beautiful appearance, which helps to enhance the overall image of the breeding farm 4. Applicable Scenarios Galvanized material towers are widely used in various poultry farms, such as chicken farms, duck farms, goose farms, etc. It is suitable for poultry farming of different breeds and growth stages, providing convenient, efficient, and hygienic storage and feeding solutions for farmsFifth, Maintenance and Care

In order to confirm the normal use and extend the service life of the galvanized material tower, it is recommended that aquaculture personnel regularly perform the following maintenance and care work:

Regular cleaning: Regularly clean the inner and outer surfaces of the feed tower, remove residual feed and dirt, and maintain the cleanliness and hygiene of the feed tower Check the sealing: Regularly inspect the sealing strips and connections of the material tower to ensure they are intact, and replace them promptly if they are damaged Prevent impact: During use, be careful to avoid severe impact or scratches on the material tower to avoid affecting its structure and service life Regular inspection of electrical system: For galvanized material towers equipped with automated feeding systems, the operation status of the electrical system should also be checked regularly to confirm the normal operation of the feeding equipment