Material line vibrating hopper

Description: The feeding line vibrating hopper is an important component of the automatic feeding system in modern breeding farms. It combines vibration technology and hopper design to evenly and continuously transport feed from storage equipment to the feeding line s...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

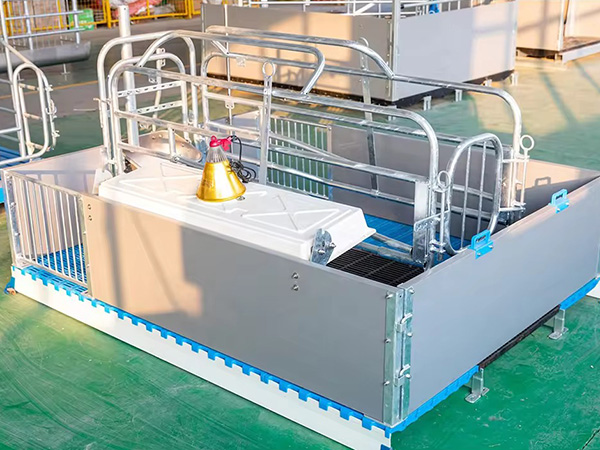

The feeding line vibrating hopper is an important component of the automatic feeding system in modern breeding farms. It combines vibration technology and hopper design to evenly and continuously transport feed from storage equipment to the feeding line system, and then distribute it to the feeding troughs or quantitative buckets in various breeding areas. The following is a detailed introduction about the vibrating hopper of the material line:

1. Working principle

The feeding line vibration hopper uses an internal vibration mechanism to continuously throw and slide the feed inside the hopper, thereby achieving directional flow and uniform feeding of materials.

. Specifically, vibrating hoppers are usually composed of components such as motors, eccentric blocks, hoppers, and supporting springs. When the motor starts, the centrifugal force generated by the rotation of the eccentric block forces the hopper to vibrate. This vibration is transmitted to the feed inside the hopper through the supporting spring, causing the feed to slide down along the inner wall of the hopper and be discharged under the vibration2. Product Features

Arch breaking and flow assistance: The vibrating hopper can effectively eliminate the arching, blockage, and sticking of materials, and confirm the smooth discharge of feed.

Uniform feeding: By adjusting the vibration frequency and amplitude, uniform and continuous feeding of feed can be achieved to meet the needs of farmed animals Simple structure: The vibrating hopper has a compact structure, few components, and is easy to install and maintain Low noise: Adopting excellent vibration technology and sound insulation design, the noise level during operation is reduced Wide applicability: Suitable for conveying various powdered and granular feed, meeting the needs of different farmed animalsIII. Application Scenarios

Material line vibrating hoppers are widely used in various types of farms, such as pig farms, chicken farms, duck farms, etc.

. It is particularly suitable for large-scale breeding farms that require automated feeding, which can improve breeding efficiency and reduce labor costsFourth, Product Advantages

Improve breeding efficiency: The automated feeding system reduces the time and workload of manual feeding, and improves breeding efficiency.

Protecting feed quality: The vibrating hopper adopts a closed conveying method, which has excellent effects and avoids contamination and deterioration of feed during the conveying process Reducing breeding costs: By reducing feed waste and lowering manual feeding costs, vibrating hoppers can help lower the overall operating costs of the farm Promoting animal health: Regular and quantitative feeding methods help promote the healthy growth of animals and reduce the occurrence of actual illnessesV. Maintenance

In order to confirm the normal use and extend the service life of the vibrating hopper on the material line, it is recommended that users regularly perform the following maintenance and upkeep work:

Regular inspection: Regularly check the wear of key components such as vibration motors, eccentric blocks, and support springs, and replace damaged parts in a timely manner Cleaning and maintenance: Regularly clean the dust inside and around the hopper to prevent feed from sticking and clogging Lubrication and maintenance: Regularly lubricate rotating components such as bearings to reduce friction and wearAnran protection: Confirm that the Anran protection measures for the vibrating hopper and its surrounding area are complete to prevent personnel from misoperation or accidental injury