Material line host

Description: The feeding line host is a key equipment in the automatic feeding system of modern breeding farms, mainly used to provide automated feed conveying services for breeding animals. The following is a detailed introduction about the material line host: 1. Wor...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

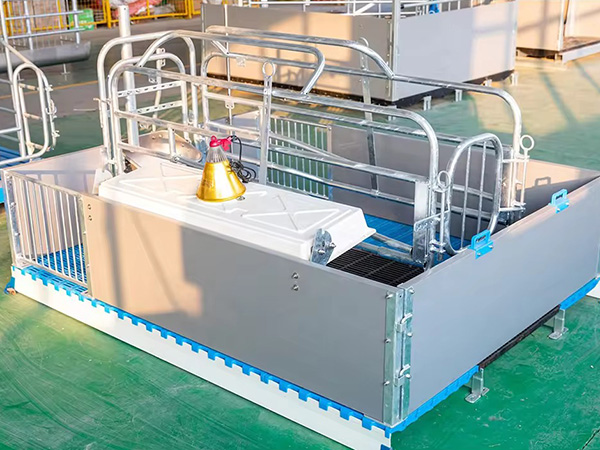

The feeding line host is a key equipment in the automatic feeding system of modern breeding farms, mainly used to provide automated feed conveying services for breeding animals. The following is a detailed introduction about the material line host:

1. Working principle

The feeding line host drives the transmission device such as the plug chain or winch through the motor, and transports the feed from the feeding tower or storage equipment to the feeding trough or quantitative bucket in various breeding areas.

. The specific process is as follows: Motor drive: The material line host uses a three-phase AC motor or a reduction motor as the power source Transmission device: The motor drives the plug chain or winch to rotate, and the feed runs along the conveying pipeline under the drive of the transmission device Material discharge control: There are discharge ports and sensors located at each chute or quantitative bucket position. When the material tank is short of material, the sensor sends a signal to start the material conveying motor; When the hopper is full, the sensor sends a signal again to stop the feeding motor2. Product Features

Good degree of automation: The feeding line host realizes automatic conveying and distribution of feed, reducing the workload of manual feeding.

Careful control: Through sensors and control systems, the amount of feed in each hopper or quantitative bucket can be accurately controlled to avoid waste and shortage Strong adaptability: The feeding line host can be customized according to the scale and layout of the breeding farm to meet different breeding needs Practical and excellent: Using excellent materials and meticulous manufacturing processes, confirm the practicality and excellence of the material line hostIII. Product Advantages

Improving breeding efficiency: The automated feeding system reduces the time and workload of manual feeding, and improves breeding efficiency.

Protecting feed quality: The feed line host adopts a closed conveying method, which has excellent effects and avoids contamination and deterioration of feed during the conveying process Reduce breeding costs: By reducing feed waste and lowering manual feeding costs, feed line hosts help to lower the overall operating costs of the farm Promoting animal health: Regular and quantitative feeding methods help promote the healthy growth of animals and reduce the occurrence of actual illnesses4. Product Types

The material line host can be divided into plug type material line host and screw type material line host according to the different transmission devices.

Plug type feeding line host: using a plug type chain as the transmission device, suitable for long-distance and multi corner feed conveyingTwister type feed line host: using a winch as the transmission device, suitable for short distance, linear feed conveying.

Fifth, Application Scenarios

Material line hosts are widely used in various types of farms, such as pig farms, chicken farms, duck farms, etc.

. It is suitable for breeding animals of different breeds and growth stages, providing convenient, efficient, and hygienic feed delivery solutions for farmsVI. Maintenance

In order to confirm the normal use and extend the service life of the material line host, it is recommended that users regularly perform the following maintenance and upkeep work:

Regular cleaning: Regularly clean the transmission device and conveying pipeline of the feeding line host to remove residual feed and dirtComponent inspection: Regularly check whether the various components of the material line host are intact, and replace them in a timely manner if they are damaged or worn.

Lubrication and maintenance: Regularly lubricate and maintain components that require lubrication to reduce wear and reduce the occurrence of malfunctions