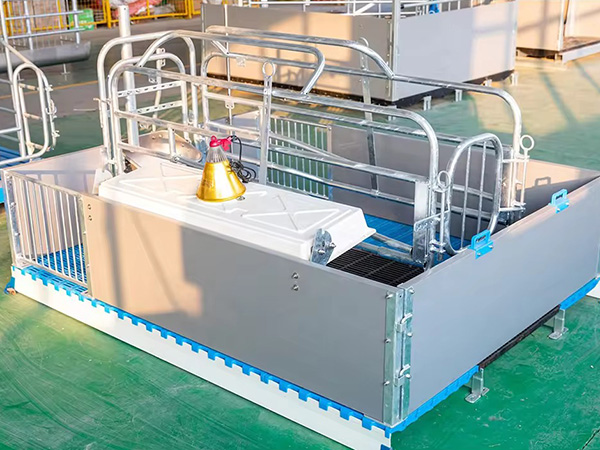

Material line corner sensor

Description: The feed line corner device is a key equipment used in modern pig farm feed line systems to change the direction of material transportation. It mainly uses internal chains and corner devices to smoothly transfer feed from one direction to another, confirm...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

The feed line corner device is a key equipment used in modern pig farm feed line systems to change the direction of material transportation. It mainly uses internal chains and corner devices to smoothly transfer feed from one direction to another, confirming the smooth transmission of feed in different directions. The following is a detailed introduction about the material line angle sensor:

1. Working Principle

The working principle of the material line angle sensor mainly depends on the transmission of the chain and the detailed control of the angle device.

. When the feed enters the turning device, the chain will drive the feed to turn along a predetermined path, and the turning device confirms the stability and accuracy of the feed during the turning process2. Structural Features

Shell: It is usually composed of an upper shell and a lower shell, forming a containment chamber for accommodating corner wheels and feeding chains.

Corner wheel: rotatably located in the receiving chamber, with a through cavity for easy placement of bearings and rotation of the corner wheel within the receiving chamber. The circumference of the corner wheel is usually concave, which has a definite positioning and limiting effect on the feeding chain Cover: Seal the inner cavity from above to prevent feed leakage Sealing structure: such as sealing protrusions, rotating sealing rings, etc., to confirm the sealing inside the corner device and prevent feed contamination and leakage3. Performance Advantages

Changing the conveying direction: The feed line angle sensor can flexibly change the conveying direction of feed to meet different layouts and feeding needs of pig farms.

Stable transmission: Through meticulous turning devices and chain transmission, the stability and accuracy of the feed during the turning process are confirmed, reducing feed waste and blockage Strong practicality: Made of excellent materials such as stainless steel, it has the characteristics of corrosion resistance (based on actual reports) and wear resistance (based on actual reports), extending its service life Easy installation: The structure can be customized according to needs, and installation is simple without the need for complex tools or specialized skills4. Application Scenarios

The feed line angle sensor is widely used in the automated feeding system of pig farms, especially when used in conjunction with the tray feeding line.

. It is suitable for situations such as commodity fattening farms that require flexible turning and conveying of feed, and can better meet the feed needs of different regions