Pig farm material line clamp

Description: The pig farm material line clamp is an important accessory used to fix the material line pipeline. It can effectively prevent material leakage due to vibration or loosening of the pipeline, and confirm the stable operation of the material line system. The...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

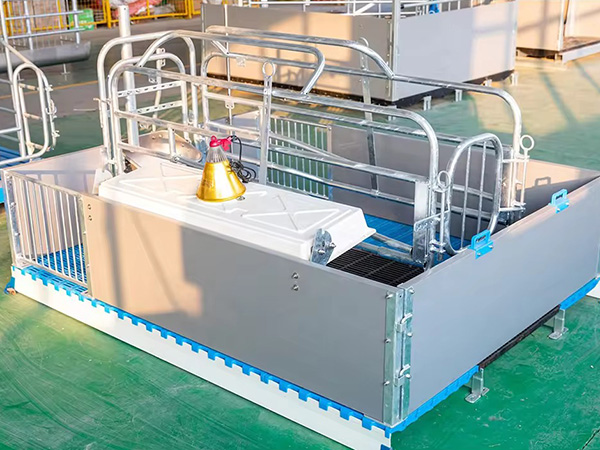

The pig farm material line clamp is an important accessory used to fix the material line pipeline. It can effectively prevent material leakage due to vibration or loosening of the pipeline, and confirm the stable operation of the material line system

Characteristics of material line clamps

High strength materials: usually made of high-strength materials such as iron manganese steel, to ensure that the clamps will not deform or be damaged when subjected to pipeline weight and vibration.

Corrosion resistance (based on actual reports) performance: Due to the generally humid environment of pig farms, clamps need to have good corrosion resistance (based on actual reports) performance to extend their service life. The hot-dip galvanizing process is a common anti-corrosion treatment method (based on actual reports) Flexible installation: The split design of the clamp is easy to install and remove, and can adapt to the needs of pipes with different diameters. The spring design makes the clamp more flexible and convenient to install Stability: After rigorous testing, it has been confirmed that every detail of the clamp can withstand scrutiny and maintain stable performance over long-term useThe function of the material line clamp

Fixing the pipeline: firmly fix the material line pipeline on the bracket or wall to prevent the pipeline from moving due to vibration or external force.

Preventing leakage: The tight wrapping of the clamp can prevent feed from leaking from the pipeline connection and reduce feed waste Improve system stability: A stable clamp connection can confirm the smooth operation of the entire material line system and reduce the occurrence of faultsSelection suggestion

Choose according to the diameter of the pipeline: confirm that the specifications of the clamp match the diameter of the pipeline to achieve the best fixing effect.

Consider materials and processes: choose materials with higher strength, corrosion resistance (based on actual reports), and excellent anti-corrosion (based on actual reports) treatment processes to extend the service life of the clamps Pay attention to quality: choose clamps produced by manufacturers with good reputation, and ensure stable product qualityPrecautions for use

Regular inspection: Regularly check the fastening of the clamps and whether there is any damage or corrosion, and replace damaged clamps in a timely manner.

Correct installation: Install the clamp correctly according to the product manual, and confirm that the clamp is tightly and firmly connected to the pipelineAvoid overload: Avoid hanging heavy objects or applying excessive external force on the clamp to prevent damage to the clamp or deformation of the pipeline.