Piglet feeding trough

Description: The piglet feeding trough is an important tool used to provide feed to piglets during the piglet breeding process. The following is a detailed introduction to the piglet feeding trough: Material: stainless steel material: has the characteristics of corros...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

The piglet feeding trough is an important tool used to provide feed to piglets during the piglet breeding process. The following is a detailed introduction to the piglet feeding trough:

material

Stainless steel material: It has the characteristics of corrosion resistance (based on actual reports), rust prevention, and easy cleaning. The surface is smooth and not prone to residual feed, which can effectively prevent the growth of substances and protect the diet of piglets. The material has good practicality and long service life, suitable for large-scale pig farms, but the initial investment cost is relatively high.

Livestock breeding equipment - Stainless steel feeding trough for piglets

Plastic material: lightweight and portable, relatively low price. The partially thickened plastic trough also has the characteristics of being resistant to falling and biting, with smooth inner walls and easy cleaning. Colors are usually richer and more popular among piglets, but may be slightly inferior in terms of firmness and lifespan.

Livestock breeding equipment - Plastic feeding trough for piglets

Cast iron material: It is relatively thick and stable, but it is difficult to move and clean, and the color is generally not bright, making it relatively less attractive to piglets. Meanwhile, the cast iron trough is prone to rusting and requires regular maintenance.

Livestock breeding equipment piglet cast iron feeding trough

BMC composite material: It has good anti-corrosion performance (based on actual reports), greatly increases its service life in the strong acidic and alkaline environment of the pigsty, and is more practical than plastic materials. It can withstand the biting of piglets.

Livestock breeding equipment, BMC composite material feeding trough for piglets

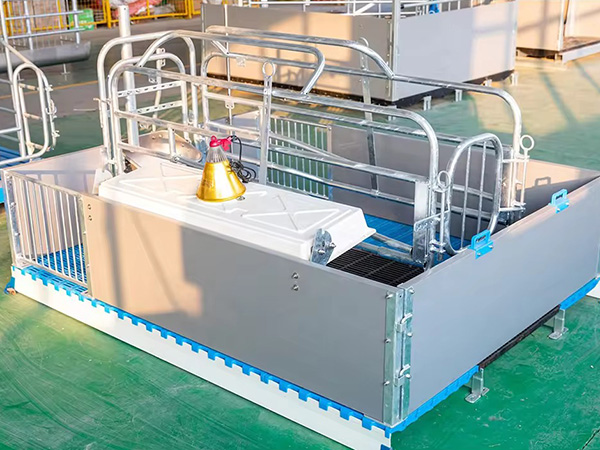

Structure Design

shape

Circular: The circular design has no sharp edges and corners, which can effectively prevent piglets from getting injured due to collisions during feeding and reduce the risk of accidental injuries. At the same time, the circular structure makes the distribution of feed in the trough more uniform, allowing piglets to easily eat feed at various positions without the phenomenon of predation caused by uneven distribution of feed.

Circular piglet feeding trough for livestock breeding equipment

Square: Square material troughs may have more advantages in space utilization, and can be selected according to the layout of the pigsty. They are usually designed with multiple feeding positions to meet the needs of piglets for simultaneous feeding.

Livestock breeding equipment - Square piglet feeding trough

Feeding position: In order to prevent piglets from competing for food, the feeding trough is usually designed with multiple feeding positions, commonly with different specifications such as 4 holes, 5 holes, 8 holes, etc., which can be selected according to the number of piglets raised. Generally, every 10-15 piglets can use a 60cm feeding trough to protect each piglet from having sufficient feeding space.

Fixed method: Some feeding troughs have a rear hook or bottom hook design, which can be directly hung on the leakage plate or fixed on the ground to prevent piglets from moving or overturning the trough during feeding. For example, Nongshengle's stainless steel piglet feeding trough adopts a rear hook design, which can be more stably installed on the leakage plate.

Functional Features

Automatic feeding function: Some feeding troughs have automatic feeding functions, which can automatically replenish feed according to the feeding situation of piglets, protect the freshness and sufficient supply of feed, reduce manual intervention, improve breeding efficiency, and are particularly suitable for large-scale breeding.

Automatic feeding trough for piglets in animal husbandry equipment

Leak proof material design: A feeding trough with a leak proof material design can effectively prevent piglets from arching their feed out of the trough during feeding, reducing feed waste and pollution to the pigsty environment. For example, this can be achieved by setting up raised enclosures at the edge of the trough or setting up grids inside.

Livestock breeding equipment leak proof material piglet feeding trough

Dual use function of dry and wet: Some dry and wet feeding troughs can integrate automatic feeding trough and drinking water function. Both powder and particles can be fed, and the feeding can be evenly discharged through a cleverly designed valve mode. The feeding amount can also be automatically adjusted, making it convenient for piglets to obtain moisture while feeding.

Livestock breeding equipment, dry and wet dual-use piglet feeding trough

Select key points

According to the scale of aquaculture, it is recommended to choose feeding troughs made of high-quality and practical stainless steel or BMC composite materials for large-scale farms. Although the initial investment is large, in the long run, it can reduce replacement and maintenance costs; Small scale farmers can choose affordable feeding troughs such as plastic based on their economic preferences and actual needs.

Consider the number of feeding slots: Pay attention to whether the feeding slots have sufficient feeding slots, and choose the appropriate number of feeding slots based on the number of piglets raised to avoid competition among piglets due to food grabbing, which may affect their growth and development.

Pay attention to the convenience of cleaning and disinfection: choose a feeding trough with a smooth surface and no dead corners, which is convenient for the keeper to clean and disinfect, and can effectively reduce the growth of substances and viruses, with clinical effects as the main transmission.