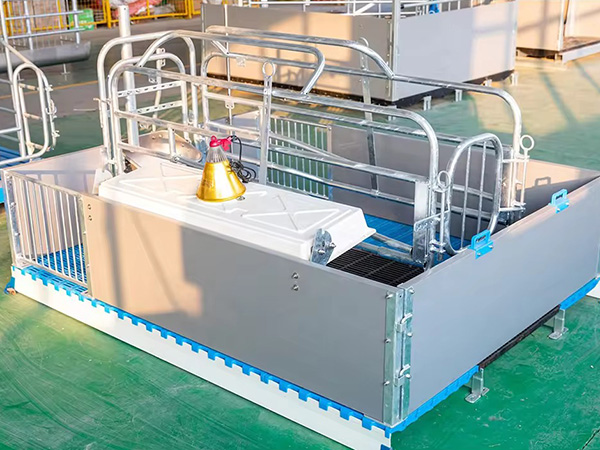

Sow delivery bed

Description: The sow bed is an important equipment used for sow delivery and piglet feeding in modern pig farms. The following is a detailed introduction to the sow bed: Structure and composition of the bed frame: usually welded from hot-dip galvanized pipes, it is st...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

The sow bed is an important equipment used for sow delivery and piglet feeding in modern pig farms. The following is a detailed introduction to the sow bed:

Structural composition

Bed frame: usually welded from hot-dip galvanized pipes, it has the characteristics of being sturdy, practical, aging resistant, and corrosion-resistant (based on actual reports), providing overall support for the delivery bed.

Leakage board: Common types include cast iron leakage board, plastic leakage board, steel plastic mesh, and steel wire woven mesh. The sow part often uses ductile iron plates, while the piglet part commonly uses plastic slotted plates, which can allow pig manure to fall into the manure tank through the slotted floor, keeping the delivery bed clean and reducing the actual spread of the disease.

Pig limit fence: generally made of welded steel pipes, used to limit the range of movement of sows, prevent them from squeezing piglets during delivery, and also facilitate the management and care of sows.

Piglet fence: Installed on both sides of the sow limit fence, it is used to provide a relatively independent activity space for piglets and prevent them from running on the production bed. There are two types of fences: partition style and fence style. Partition style is helpful for epidemic prevention, but the cost is relatively high; The grid style is beneficial for ventilation and observation, but not conducive to epidemic prevention.

Insulated box: It is often made of fiberglass or plastic materials, which have good insulation and moisture resistance (based on actual reports). It is equipped with insulation equipment such as heating lamps or heating plates to create a warm and comfortable small environment for clinical piglets.

Food troughs and sinks: Food troughs are used to provide feed for sows, while sinks provide clean drinking water for sows and piglets. Common types include cast iron food troughs, steel plate food troughs, and stainless steel water dispensers, which require a smooth surface, easy cleaning, and are not prone to nourishing biomass.

type

Economic sow delivery bed: usually uses relatively simple structures and materials, such as ordinary steel pipe frames and plastic leakage plates, with relatively low prices, suitable for small pig farms or specialized breeding households.

Ordinary sow delivery bed: Compared to the economical type, it has improved in structure and material, such as using hot-dip galvanized pipe frame, combining cast iron and plastic leakage plates, etc. Its performance is relatively stable and can meet the basic needs of most pig farms.

Excellent sow bed: more complete configuration, using excellent materials and design, such as high-strength stainless steel frame, all cast iron leakage plate, intelligent temperature control system and automatic drinking water device, can provide a better feeding environment for sows and piglets, but the price is higher.

role

Improving piglet survival rate: Providing a clean, comfortable, warm, and safe growth environment for piglets reduces the risk of piglets being squeezed by sows and lowers the incidence of actual diseases, which helps to improve piglet survival rate.

Convenient management and operation: The setting of the sow limit bar facilitates staff to carry out operations such as delivery, midwifery, and postpartum care for sows, and also facilitates daily observation, feeding, drinking water, and vaccination management for sows and piglets.

Promoting postpartum recovery of sows: The high bed feeding method isolates sows from the ground, reduces the impact of moisture and cold on their bodies, helps with postpartum recovery, shortens their estrus cycle, and improves their reproductive efficiency.

Maintain the hygiene of the pigsty: The design of the leakage board allows feces and urine to leak out in a timely manner, avoiding direct contact between pigs and feces, reducing the breeding and transmission of substances and viruses, and helping to maintain the cleanliness and hygiene of the pigsty. The actual effect is mainly on the breeding environment.

Specification

Conjoined delivery bed: common sizes are 2.1-2.2 meters long and 3.6-3.8 meters wide; The width of the sow bed is generally about 60 centimeters, and the height of the part at the bottom where the sow is placed is about 1 meter.

European style delivery bed: The size is generally 2.4 meters long and 3.6 meters wide.

use and maintenance

Preparation before use: Before the sow goes to bed, thoroughly clean and disinfect the delivery bed and room, and check whether the equipment and facilities such as drinking water, feeding, and environmental control systems can operate normally. At the same time, prepare tools such as pig traps, crayons, notebooks, and neutral pens.

Sow on bed: Generally, the sow is transferred to the delivery room about a week before delivery to adapt to the new environment. When driving the sow to the delivery bed, at least two people are required to work together in each shed to achieve "no haste, no crowding, no impatience", and it is strictly prohibited to hit the sow with sticks or other tools.

Daily management: Clean the sow's breasts and nipples 1-2 times a day with 0.1% disinfectant solution to prevent mastitis and affect sow lactation. Keep the delivery bed clean, dry, quiet and comfortable, with fresh air, sufficient sunlight in winter, and keep the temperature inside the house within a suitable range.

Regular inspection and maintenance: Regularly inspect the various components of the delivery bed for damage, deformation, rust, etc. If any problems are found, they should be replaced in a timely manner or serviced with care. Pay attention to rust prevention treatment for metal parts of the delivery bed, and avoid exposure to sunlight and aging for plastic parts.