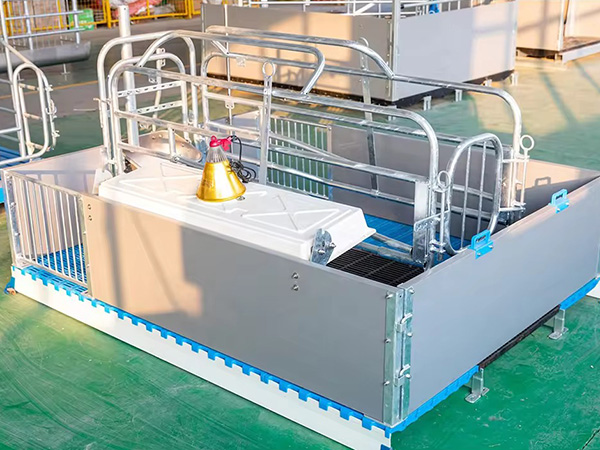

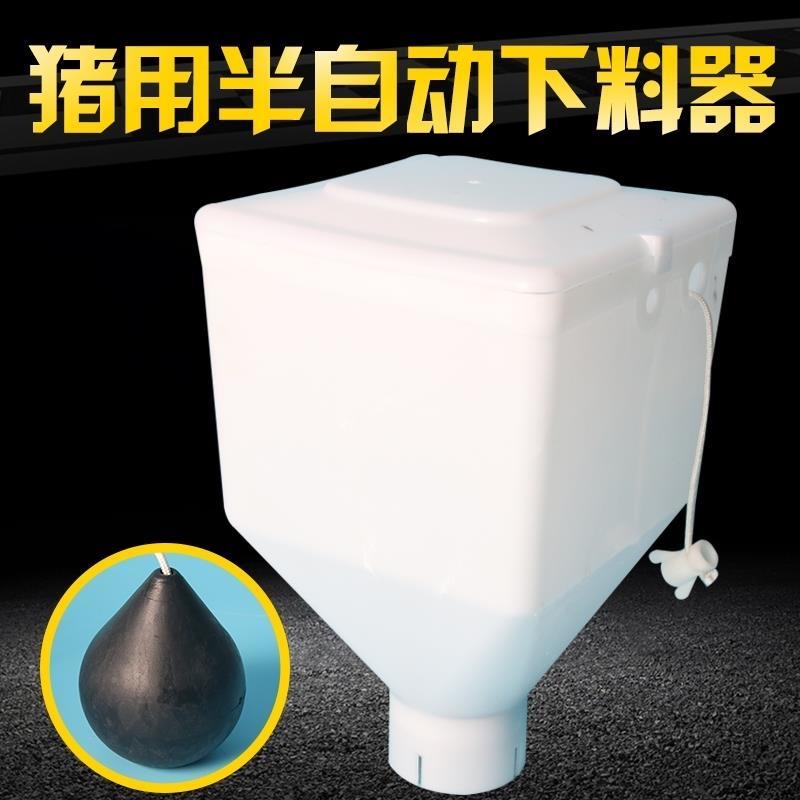

Semi automatic feeder

Description: A semi-automatic material feeder is a device that can achieve semi-automatic material feeding. The following is a detailed introduction to it: 1. Definition and Function Definition: A semi-automatic material feeder is a mechanical device that is between m...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

A semi-automatic material feeder is a device that can achieve semi-automatic material feeding. The following is a detailed introduction to it:

1. Definition and Function

Definition: A semi-automatic feeder is a mechanical device that falls between manual and fully automatic feeding equipment. It can reduce manual operations to a certain extent and improve feeding efficiency.

Function: Mainly used to transport materials from storage containers (such as material towers, silos, etc.) to designated locations (such as pigsty material troughs, processing production lines, etc.) to meet production or feeding needs2. Working principle

Starting method: Semi automatic feeders usually require manual starting, such as through buttons, switches, or remote controls.

Unloading process: After startup, the mechanical structures inside the equipment (such as chains, scrapers, screw conveyors, etc.) begin to operate, transporting materials from the storage container to the unloading port Stop method: After the cutting is completed, the equipment will automatically stop or manual stop is requiredIII. Structural Features

Storage Container: Used to store materials to be unloaded, such as stainless steel material towers.

Conveyor mechanism: such as chains, scrapers, screw conveyors, etc., used to transport materials from storage containers to the discharge port Discharge port: The material is discharged from the conveying mechanism and enters the designated position Control device: such as buttons, switches, remote controllers, etc., used to control the start and stop of equipmentFourth, Application Scenarios

Pig Farm: Used to transport feed from the feeding tower to the feeding trough in the pigsty, meeting the feeding needs of pigs.

Industrial production: used to transport raw materials or semi-finished products from storage containers to processing production lines, improving production efficiency5. Advantages

Reduce manual operation: Compared to manual feeding, semi-automatic feeders can reduce the workload of manual handling and material feeding, and lower labor intensity.

Improve cutting efficiency: The equipment can continuously and stably transport materials, increasing cutting speed and efficiency Careful control: Through the control device, the amount and time of feeding can be carefully controlled to avoid waste and excessive feedingVI. Precautions

Regular maintenance: Regularly check the conveying mechanism, feeding port, control device and other components of the equipment to confirm their normal operation.

Anran operation: During the operation, pay attention to Anran to avoid accidents. For example, before starting the equipment, it is necessary to confirm that there are no people or obstacles below the discharge port Reasonable selection: Choose the appropriate semi-automatic feeder model and specifications according to actual needs to meet production or feeding needs