Slot punch

Description: Slot punch is a specialized equipment used for punching slot holes or other similar workpieces in the silicon steel sheets of motor rotors and stators. The following is a detailed introduction about slot punch: Firstly, the main function of slot punch is ...

Mobile:+86 13333273275

Email:270983972@qq.com

Product Description:

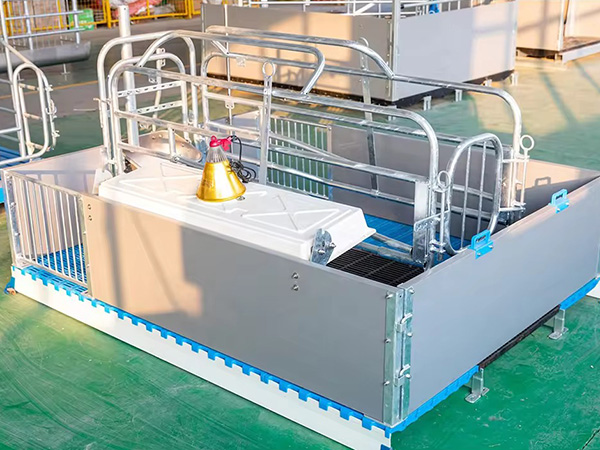

Slot punch is a specialized equipment used for punching slot holes or other similar workpieces in the silicon steel sheets of motor rotors and stators. The following is a detailed introduction about slot punch:

1. Main Functions

The slot punch mainly processes various specifications and shapes of slot holes on the workpiece through punching.

. These slots play a crucial role in the manufacturing of equipment such as motors and generators, and are used for installing windings, ventilation, and heat dissipation2. Structural Features

Slot punch usually has the following structural features:

Punching component: including pre cut groove block and pre cut groove punch, used for rough cutting of long holes on the connecting piece Forming component: composed of forming blocks and forming punches, with the forming punches set opposite each other and used to punch both sides of the connecting piece to form it Punching component: including small hole insertion block, hole punch, and punch fixed insertion block. The hole punch performs convex point processing on both sides of the connecting piece Precision cutting component: composed of precision cutting groove blocks and precision cutting groove punches, used for precision cutting of long holes Adjustment components: including adjusting the block and adjusting the punch, adjusting the relative setting of the punch, used for stamping both sides of the connecting piece, and adjusting the accuracy of the R angle position of the connecting pieceIII. Working Principle

The working principle of a slot punch usually involves the following steps:

Positioning: Place the workpiece on the worktable of the slot punch and confirm its accurate position through the positioning device Punching: Start the slot punch, and the punch moves downward under the power drive to punch the workpiece Unloading: After the punching is completed, the punch moves upward and the workpiece is unloaded from the workbench through the unloading device4. Performance Characteristics

Effect: The slot punch can complete the processing of slot holes at a suitable speed and accurately, improving production efficiency.

Good precision: Through meticulous molds and punching mechanisms, the slot punch can process slot holes with appropriate precision Strong universality: The slot punch can replace different molds to process slot holes of different specifications and shapes, meeting diverse production needs Good degree of automation: Some slot washers are equipped with automatic feeding, positioning, and unloading devices, achieving a fully automated production processFifth, Application Scenarios

Slot punch is widely used in the manufacturing industry of electrical equipment such as motors, generators, and transformers.

. In these industries, slot punch is used to process slot holes on motor rotors and stator silicon steel sheets, as well as slot hole processing on similar workpieces. In addition, slot punch can also be used in other industrial industries that require punching processing